limitations of torsion test|torsion testing pdf : trade There are two broad categories for torsional testing: torsional properties of a material or product (such as ultimate shear strength and modulus of elasticity, etc). operational testing of actual products, simulating actual conditions the . Textos para tocar cicatrizes Autor: Igor Pires , Anália Moraes | Casa Dobra Número de Páginas: 296 Igor Pires, autor best-seller e criador de Textos cruéis demais para serem lidos rapidamente, lança seu quinto livro Com mais de 1 milhão de exemplares vendidos, Igor Pires lança sua mais nova obra, Textos para tocar cicatrizes, em que se debruça .

{plog:ftitle_list}

Resultado da Acessar o CELK SAÚDE® Usuário Senha Acessar. Versão 3.1.221 | i-096ece14a356099b2

Torsion testing predicts a material’s behavior under twisting forces by assessing key properties such as torsional strength, shear modulus, yield strength in torsion, ductility, and brittleness. It enables the understanding of fatigue behavior, .Equipment Limitations: Torsion testing requires specialized equipment capable of applying and measuring rotational forces, which can be a significant investment. Inconsistent Results: . Torsion testing stands as a fundamental mechanical assessment technique aimed at revealing the mechanical attributes of materials when subjected to torsional or .There are two broad categories for torsional testing: torsional properties of a material or product (such as ultimate shear strength and modulus of elasticity, etc). operational testing of actual products, simulating actual conditions the .

what is torsion testing

what is a torsion tester

Under compression the microscopic flaws are pressed together, increasing resistance and causing failure that depends on the normal compressive and shear stresses. Use a failure .Longer gauge lengths and too small wall thickness cause instabilities (see Fig. 3). With the torsion test, rel-atively high deformations are possible without necking or buckling with an .MECHANICAL PROPERTIES AND PERFORMANCE OF MATERIALS: TORSION TESTING* MGJ/08 Feb 1999. PURPOSE. The purpose of this exercise is to obtain a number of .

This article reviews the common methods of shear and multiaxial testing for the evaluation of engineering components such as fasteners and mill products. It discusses shear test .

Study with Quizlet and memorize flashcards containing terms like Specify three assumptions that have been made in deriving the equations used in this experiment., Name three limitations of torsion formulae., Can the same equations be used with a square shaft? Explain. and more.However, the torsion test also permits the shear but much larger deformation than in the simple shear test. The mode of deformation in torsion is easy to describe with precision, and it is easy to study the behaviour of the material in the plastic domain. Typically, the thin-walled tubular or solid cylindrical specimen is placed in a torsion .Limitations of the torsion shear test. . The triaxial test is a practical and reliable method of determining the Mohr-Coulomb envelope for soils at high values of direct pressure. Recommended articles. References (5) A.W. Bishop et al. .

custom moisture meter reviews 2017

torsion testing pdf

custom moisture meter reviews 2018

Tensile testing on a coir composite. Specimen size is not to standard (Instron). Tensile testing, also known as tension testing, [1] is a fundamental materials science and engineering test in which a sample is subjected to a controlled tension until failure. Properties that are directly measured via a tensile test are ultimate tensile strength, breaking strength, maximum .Circular shaft experiencing an axial torque. A solid, circular cross-sectioned shaft experiences an axial torque T, as shown above.. Angle of twist The hypothesis used in developing the stress and strain in the shaft is that all points on a cross-section of .ME 354 LAB #4: DISCUSSION OF THE TORSION TEST Each lab section performed a torsion test of a cylindrical 6061-T6 aluminum specimen. The specimen was mounted in a Technovate model 9041 Torsion Tester. A top view is shown in Figure 1. The cylindrical specimen was clamped in two 52.3 mm dia grips. The top grip wasSome challenges and limitations of the torsion test; Torsion testing is a common method for evaluating the mechanical properties of materials, such as modulus of stiffness, shear stress, and shear strain. However, like any other testing technique, it has some challenges and limitations that you should be aware of before performing or .

Advantages and Limitations. Torsion testing, a vital tool in the engineering sector, offers several notable advantages. It provides essential data on how materials and components behave under torsional stress, thus informing the design, manufacturing, and quality control processes. Here are some key advantages of torsion testing:

Other non-standard toughness tests that have been used to study the deleterious effects of hydrogen include the in situ spiral notch torsion test in gaseous hydrogen , ex situ small punch test of gaseous and cathodic hydrogen pre-charged specimens , in situ small punch test in hydrogen/natural gas mixture , and burst test of steel pipes .A torsion test is a mechanical testing method that evaluates the properties of materials or devices under stress caused by angular displacement. During a torsion test, a specimen is subjected to a twisting or torsional force, which induces a torque. This test is used to measure various mechanical properties of materials, including their modulus of rigidity, shear stress, .Statics - Twisting Moments. Twisting moments, or torques, are forces acting through distances (“lever arms”) so as to pro- mote rotation. The simple example is that of using a wrench to tighten a nut on a bolt as shown in Figure 6: if the bolt, wrench, and force are all perpendicular to one another, the moment is just the force F times the length l of the wrench: \(T = F \cdot l\).

Torsion testing can help you determine if the product withstand rotational stresses. Are there other types of testing that go hand-in-hand with torsion testing? Some combination of pressure, vibration, and temperature testing is required when testing most products. That being said, my fellow Smithers engineers and I can design a custom testing . To investigate adnexal torsion, ultrasound is a good first-line diagnostic test with a pooled sensitivity of 0.79 and specificity of 0.76. Introduction Adnexal torsion (AT) is a serious gynaecological emergency that involves a partial or complete twisting of the infundibulopelvic vascular pedicle.The devices may be either be mechanical clip on or video where non-contact is a limitation, e.g. elevated temperature testing. Ultimate Tensile Strength (UTS) The UTS is the maximum stress that a specimen is exposed to during testing. This may differ from the specimen's strength when breaking depending on if it is brittle, ductile or has .

metal torsion testing

Uniaxial tensile test Uniaxial compression test Torsion test s t In the compression region, the material’s resistance to shear increases 19.5 Coulomb-Mohr Failure Theory 11/15/00 ME111 Lecture 19 8 Coulomb-Mohr Failure Theory S ut S ut −S uc s 1 s 3 (S ut,−S ut) (− , ut) (−S uc,−S uc) Coulomb-Mohr theory Modified Mohr theory

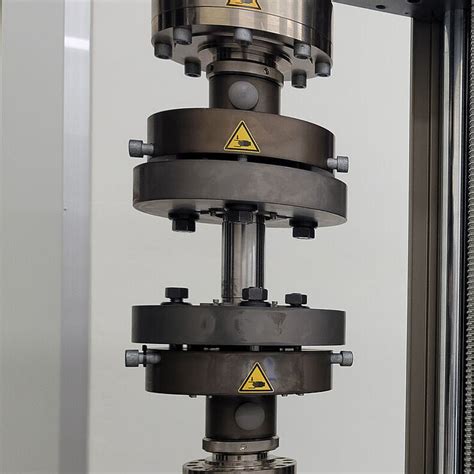

The torsion testing equipment which was used in the previous torsion test was also used in this study. Figure 1 shows an image of the stereo camera system and the inclinometer used in this study. The photogrammetric .

The torsion test provides hot ductility as dependent on temperatures and strain rates. The hot torsion test is widely used for assessing hotworkability and constitutive behavior of new materials and alloys. One of the disadvantages .

The double-torsion testing technique for fracture toughness and slow crack growth determination has been critically reviewed. The analytical compliance and finite element stress analyses of the double-torsion test specimen are summarized. The fracture toughness and crack growth testing procedure using this test configuration is described along with the applicable .The three common forms that torsion testing take include failure, proof and operational. A torsion test for failure requires that the test sample be twisted until it breaks and is designed to measure the strength of the sample. A proof test is designed to observe the material under a specified torque load over a set period of time. In research and industry, the in-plane torsion test is applied to investigate the material behaviour at large plastic strains: a sheet is clamped in two concentric circles, the boundaries are twisted against each other applying a torque, and simple shear of the material arises. This deformation is analysed within the scope of finite elasto-plasticity. An additive .

Torsion equation also known as torsion constant is derived from by considering a circular shaft. To know more on the derivation of torsion equation, please visit BYJU’S. . Test your knowledge on Torsion equation derivation. Q 5. Put your understanding of this concept to test by answering a few MCQs. Click ‘Start Quiz’ to begin! Calibrate the torsion testing equipment as explained above; Use the hexagonal sockets to grip specimen on torsion testing machine; Fix one end of specimen on input and other end on torque shaft and apply small preload; Set torque meter to zero; Start the process and twist the specimen with the strain increment of 0.5 degree until failure of .

The in-plane torsion test as firstly presented by Marciniak (1961) is ideally suited for the determination of flow curves up to high strains. An overview of the history and applications of the in-plane torsion test are summarized by Traphöner et al. (2018a).The samples of the in-plane torsion test (Fig. 1) are clamped in the center and on the outer edge and twisted against each .

custom moisture meter reviews australia

In determining the flow curve, Torsion test is used in determining strains where the strains of higher ranges (i.e., greater than 1) are achieved when compared to the uniaxial tension or compression test due to their limitations of necking and barreling respectively. Even though the torsion test is being used from long time, the specimens and . Torsion Equation Derivation. When two opposing and equal torques are applied at either end of a shaft, it is said to be in torsion. Shear stress and shear strain will arise in the material of a shaft when it is subjected to a torsion or twisting moment.. Here, we’ll take a single instance of a circular shaft that will be torn, and we’ll derive the circular shaft torsion equation.

What is Torsional Stress Test? A torsion test is a mechanical testing method that evaluates the properties of materials or devices under stress caused by angular displacement. During a torsion test, a specimen is subjected to a twisting or torsional force, which induces a torque. Torsion testing can be split into two distinct categories:

From here we can find the pure torsion formula as: $$\frac{T}{J}=\frac{\tau}{r}=\frac{G \theta}{L} $$ Limitations. Limitation of the formula discussed above: Warping: Plane section remains plane after torsion and there is no warping. Rotation: All cross-sections normal to longitudinal axis at equal distance undergo dame relative rotation.

Escolha o pneu de acordo com seu estilo. ESTRADA. AVEN.

limitations of torsion test|torsion testing pdf